Improved Control for Better Results in Metal and Coil Coating

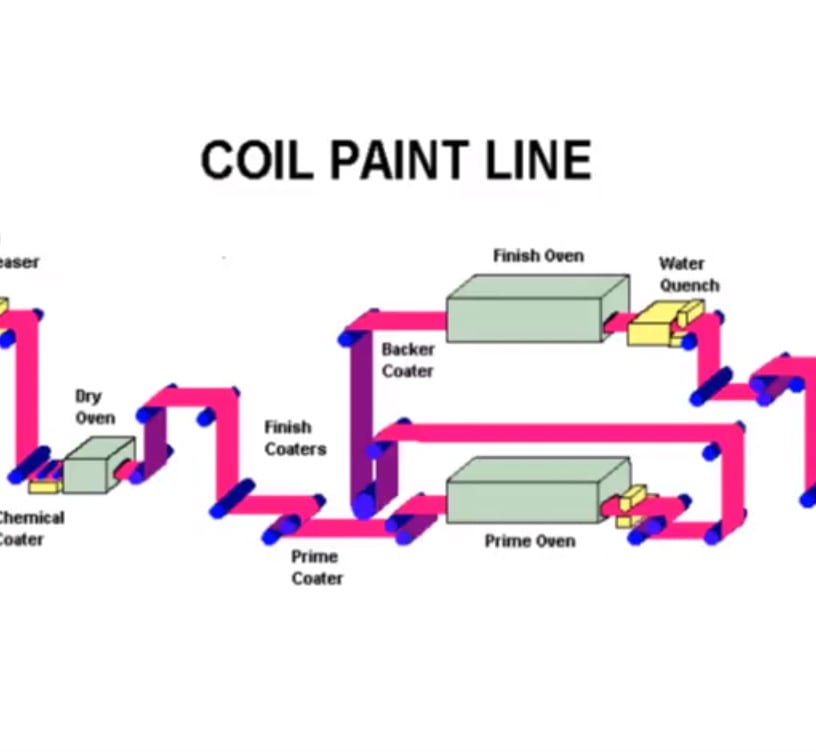

In your coil coating process, fluctuations in fluid viscosity can cause variations in film build from edge to edge, resulting in different cure rates across the face of the strip. This increases the likelihood of curing-related defects.

In coil and metal coating, the performance of the final product is dependent on the coating being of a consistent thickness along both the length and width of the coated area. Variations in coating thickness can result in color, gloss and surface finish inconsistencies, reduced corrosion protection, and shortcomings in adhesion and durability.